Product Process

Hwashin’s high-tech products establish new standards of selecting an automobile

- Product

- Product Process

Assurance of Quality

An automobile chassis & body component manufacturer

An automobile chassis & body component manufacturer

According to customer trends for pleasant and comfortable automobiles, Hwashin is doing its best to satisfy customer needs and to secure new technology and quality based on its technology skills, state-of-the-art facilities, and quality talent.

Product Process Cyber Tour

-

- 01. SLITTING PROCESS

- Slitting refers to a shearing facility used to sequentially cut a circular coil to the direction of length at a certain width and its major process is composed of uncoiler, slitter, and recoiler. Hwashin is supplying slitter products to Hwashin Group and its customers.

- The control system basically operates the SAP system and the coil management system.

-

- 02. STAMPING PROCESS

- This process is one of the most representative processes of Hwashin. With various machines including a hot stamping press, 2700-ton transfer, 2000-ton transfer, 1700-ton transfer, 1200-ton transfer, and small lines, Hwashin is supplying press products.

- The control system basically operates the SAP system and the POP system.

-

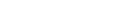

- 03. WELDING PROCESS

- This process, conducted to assemble a cross member, rear CTBA, and lower arm with press products, represent the characteristics of Hwashin well.

- The control system basically operates the SAP system and the Barcode system.

-

- 04. PAINTING PROCESS

- This process, conducted for electrodeposition coating of welded products, is composed of washing, filming, electrodeposition, and dry and the electrodeposition capacity is 30 ton. A conveyor takes around three and a half hours. The conveyor coating system is the second biggest in Korea. Its major color is black and 24-hour operation is available.

- The control system basically operates the SAP system and the Barcode system.

-

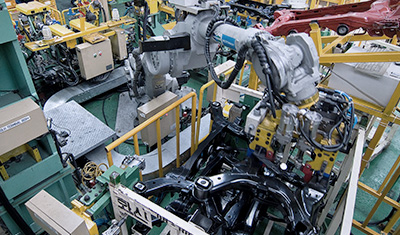

- 05. ASSEMBLY PROCESS

- This process is conducted to assemble a cross member, lower arm, and brackets with coated products. One-to-one management is conducted with the finished automobile production process of OO company. This simple-automated and mechanized process composed of compact facilities and ergonomic lines with the design considering worker safety and fatigue is maximizing customer satisfaction.

- The control system basically operates the SAP system and the Barcode system.

-

- 06. DELIVERY PROCESS

- This process refers to a work of shipping and delivering the finished products to customers by the appointed delivery dates. This process is managed in accordance with a delivery plan so that products are delivered on time.

- The control system basically operates the SAP system and the Barcode system.