R&D Area

We introduce the beginning of automobile component technology of Hwashin.

- R&D CENTER

- R&D AREA

In terms of precedent researches, Hwashin has been developing new materials and technologies through industrial-academic-research joint projects related to difficulties of industrial technology, independent researches, and national projects. As a result of its continuous research and development activities, the company received the Presidential citation in the New Technology Commercialization Part from the Ministry of Knowledge Economy, for its one of researches ‘CTBA (Coupled Torsion Beam) Development using Hot Press Forming’ in November 2009. In addition, the company is giving an impetus to new technology and material researches with its Hwashin Technology Research Center. With the goal of developing high-safety light components for eco-friendly automobiles, the company is striving for the ongoing research projects by developing chassis components such as sub-frames and lower arms using aluminum plate forming and extruding process and by studying high-strength light components using 60K or 80K high-tensile steel plates and 100K superhigh-tensile steel plates.

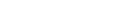

01. Hot Press Forming Tubular Beam

Advantages in NEW TYPE

- Reduction of weight by 14% compared to the old model V-BEAM

- Reduction of the number of components compared to the old model

- High-tensile steel processing using hot forming

- Increase in durability

- Reduction of process

- Reduction of weld length → Improvement of dimension quality

Comparison of Design

| Category | OLD TYPE(V-BEAM) | NEW TYPE(HPF TUBULAR BEAM) |

|---|---|---|

| Shape |  |

|

| Process | Cold Forming | HOT Press Forming |

| Tensile strength of beam |

440mpa | 1,592mpa |

| Number of components |

35ea | 23ea |

| Weight (including Bush) |

24.52kg | 21.08kg (reduced by 14%) |

| Fatigue (Cycle) | 100% | 230% |

Benchmarking

| TOYOTA VITZ | PEL ASTRA | FIAT PUNTO(SEDAN) | TOYOTA ESTIMA | ||

|---|---|---|---|---|---|

| SHAPE |  |

|

|

|

|

| OPEN DIRECTION | Lower | Front + Lower | Lower | Front + Lower | |

| Tubular Beam |

Strength | TS : 1,428Mpa | TS : 1,461Mpa | TS : 1,425Mpa | TS : 1,461Mpa |

| Dimension | ¢89.1x2.6t ,2.9t | ¢90.5x2.8t | ¢115x2.8t | ¢90.5x2.8t | |

| Process | Hot Forming | Hot Forming | Hot Forming | Hot Forming | |

Patent of Hwashin

| Patent application | NO : 10-2007-0050418 / Date : May23, 2007 / Registered | ||

| Scope | Process | ||

|

|

|

|

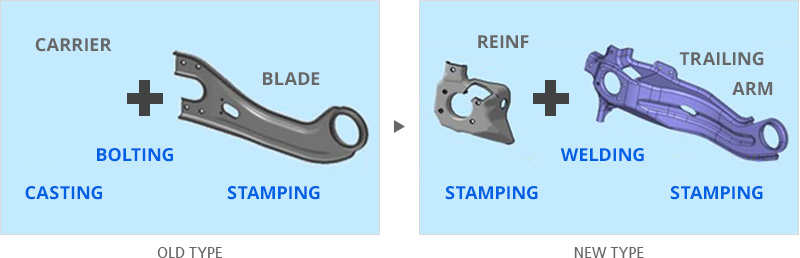

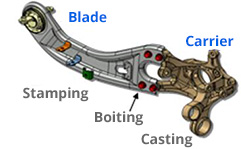

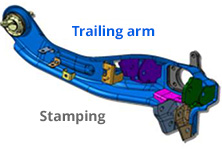

02. Trailing arm & Carrier Integration

Advantages in NEW TYPE

- Manufacturing available only with stamping which was conducted with casting, bolting, and stamping before

- Reduction of weight by 6% compared to the old model

- Cost reduction

- High-tensile steel used

Comparison of Design

| Categorys | OLD TYPE | NEW TYPE |

|---|---|---|

| Shape |  |

|

| Composition | Stamping, Casting | Stamping |

| Fixing | Bolting | Welding |

| Tensile Strength | 440Mpa | 593Mpa (High-tensile steal) |

| Weight | 13.51kg | 12.75kg (weight reduced by 6%) |

Strength Test

| Longitudinal | Lateral | Horizontal |

|---|---|---|

|

|

|

Test Result

| Category | OLD TYPE | NEW TYPE |

|---|---|---|

| SAMPLE |  |

|

| Longitudinal | 53.55(100%) | 133.62(249%) |

| Lateral | 6.56(100%) | 10.63(162%) |

| Horizontal | 1.05(100%) | 1.35(128%) |

| Result | secured the high-strength effects from all sides of the product | |

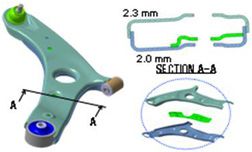

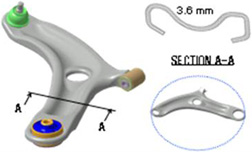

03. One-piece Lower Control Arm

Advantages in NEW TYPE

- High-tensile steel used for weight reduction

- Weight reduced compared to the old model

- Reduction of the number of components

- Reduction of weld distance → Improvement of dimension quality

Comparison of Design

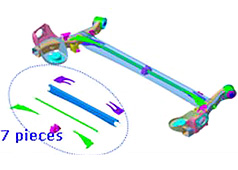

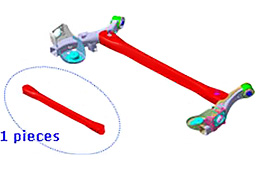

| Category | OLD TYPE (3 Pieces) | NEW TYPE (1 Piece) |

|---|---|---|

| Shape |  |

|

| Main Panel | 3Pieces (Upper + Reinf + Lower) | 1 Piece (Main Pannel) |

| Weight | 2.70kg | 2.67kg |

| Tensile Strength | 390Mpa | 561Mpa (High-tensile steel) |

| i-20 (HYUNDAI MOTOR) |

Engine – Gasoline : 1200cc | |

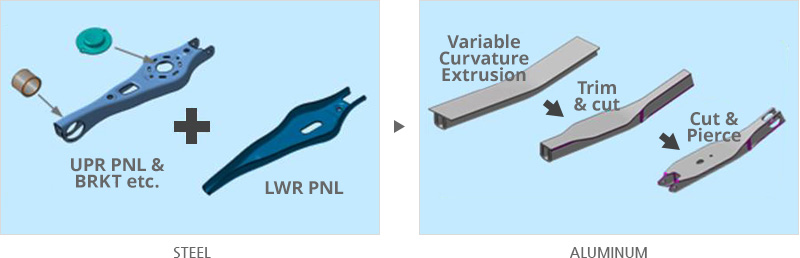

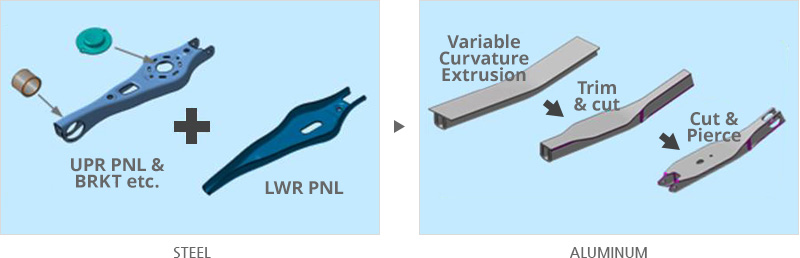

04. Aluminum Lower Control Arm

Advantages in NEW TYPE

- Reduction of weight by 50% compared to steel low-arms

- Securement of the same durability as steel

- Reduction of the number of components

- No welding → No defects on welding

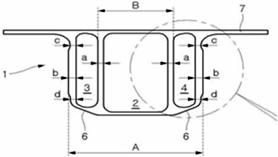

Comparison of Design

| Category | Steel Lower Arm | Aluminum Lower Arm |

|---|---|---|

| RR L/ARM |

|

|

| Weight (kg) | 3.8kg | 1.9kg (Weight reduction 50%) |

| Tensile Strength | 561Mpa (Steel) | 359Mpa (6082 Alloy) |

| Process | Stamping → Welding | Extrusion → Matching |

| Car (KIA SORENTO) |

Engine - Gasoline : 3500cc / Diesel : 2200cc | |

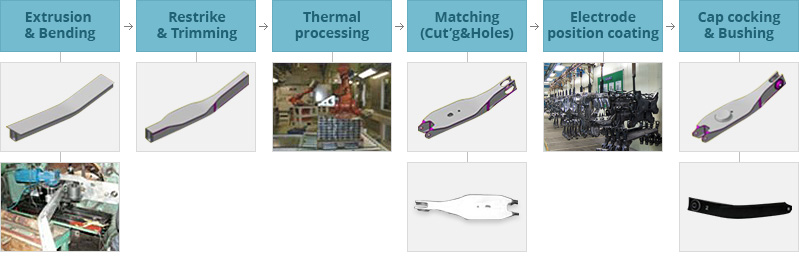

Process

* Applied electrodeposition coating for the aluminum part to satisfy customer needs

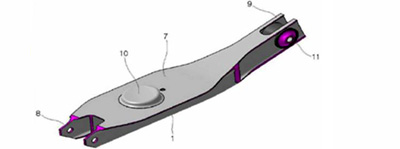

Patent of Hwashin

| Patent application | NO : 10-2007-0093624 / Date : Sep, 14, 2007 / Mass production currently under way | ||

| Scope | Shape & Structure | ||

|

|

||